Offset printing is the most common technique in commercial printing. It has been around since the 20th century, helping businesses to produce stationery, flyers, brochures, magazines and cards in bulk. Also known as offset lithography, commercial offset printing is also used to label packages such as boxes or cartons. Let's learn about Offset Printing with Giaiphapdonggoi.net!

Table of Contents [Hide]

1. What is Offset Printing?

This printing technique is called “offset” because it does not transfer ink directly onto the paper like other printing methods. Instead of going from plate to paper in two steps, the ink is first transferred to a rubber cylinder and then printed onto paper. The three-step offset method reduces wear on the lithographic plate, thus extending its life.

What is Offset Printing?

An offset printer consists of three cylinders:

Cylinder plate

Blanket cylinder offset

Impressive cylinder

In offset printing, the image area and the image area coexist on the same flat surface.

Offset printing works on the principle of oil and water separation. The plates have been treated to make the image areas attract ink and the non-image areas attract water to repel ink. When water and ink are rolled onto the plate, the oil-based ink will stick to the image while the water on the non-image area will push it out.

Some offset printers use a silicone layer that repels ink instead of water. These systems are known as 'dry' or 'waterless' offset presses.

2. 4 color printing

Offset printers use four basic ink colors: cyan (C), magenta (M), yellow (Y) and black (K). Each color is applied separately, one sheet per color. Tiny CMYK dots pressed in specific patterns form a range of colors.

Specialized offset printing can also use pre-mixed inks such as metallic and Pantone colors to produce colors that fall outside the standard print color range.

3. How offset printing works

The first cylinder used in offset printing is the 'plate' cylinder. This thin cylinder has a plastic or aluminum plate around it. Each sheet is customized with text and images to print onto paper. The plate cylinder has been pre-treated to have an ink-attracting and water-repelling image. As the disc cylinder rotates, it comes into contact with the ink and water rollers.

How offset printing works

The second cylinder is the 'blanket offset' cylinder. This cylinder is surrounded by a rubber blanket and rotates in the opposite direction of the plate cylinder. As both cylinders roll against each other, the water is forced away and the ink is transferred onto the rubber blanket. This creates a mirror image of the ink design.

The third cylinder in the offset lithography process is the 'impressive' cylinder. Made of clean steel, it rotates in the opposite direction to the blanket cylinder. The cylinder picks up the ink transfer mark as it presses the paper against the rubber blanket.

Offset printers are fast and efficient - they can print up to 18,000 sheets per hour. With each sheet of content up to 48 pages of A4 or letter size. A typical offset printer can print eight pages per sheet - that's about 120,000 pages per hour.

4. Supplied sheet vs web offset

Sheet-feed offset printers run individual sheets of various sizes. A full-size sheet measures approximately 1 meter by 0.75 meters, with half and quarter size varieties.

Web offset printers, on the other hand, are powered by a large roll of paper. This “website” goes through the press for a long time continuously.

Plate presses are practical for printing marketing materials. Web presses are more cost-effective if you print catalogs, magazines and newspaper inserts in quantities over 50,000.

5. How to start offset printing

How to start offset printing

Before starting a new print run, the plates must be replaced and several pages printed to check that the quality is optimal. This is called the “get ready” time, which can last up to 15 minutes depending on the complexity of the print job. If you are printing on a single-color press, you must clean the ink system completely before printing another color.

To begin the “getting ready” process, the plates are clamped to the plate posts and the settings are adjusted according to the ink density. An initial batch of sheets is printed at low speed and color registration and ink/water balance are checked.

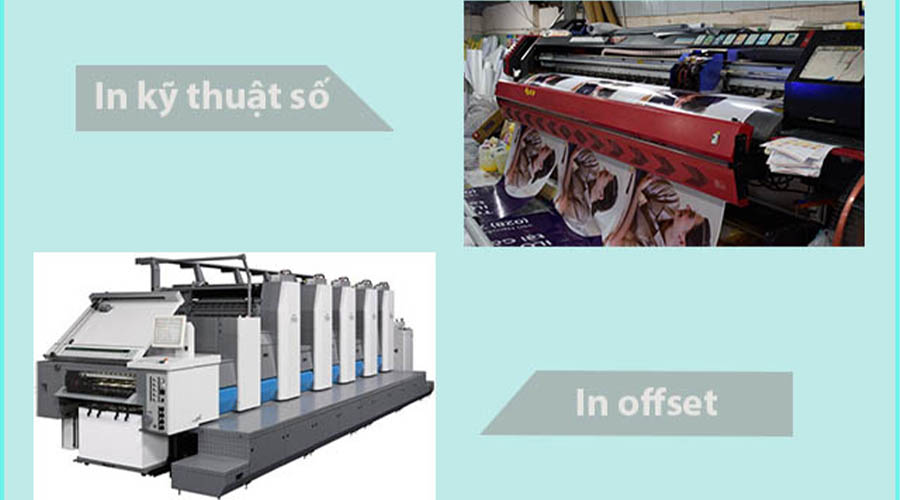

6. Offset printing vs digital printing

While offset printing produces beautiful prints at minimal cost, some projects do not require runs of thousands of copies. If your project is less than 500 pages, then the best solution is digital printing.

Offset printing vs digital printing

Advantages of digital printing:

Ideal for small print jobs (1 to 500 pages).

Easy color adjustment.

Ability to change data (name, address or number on the card can be changed easily).

There is no initial plate making cost.

Quick turn around.

Environmental friendliness.

Advantages of offset printing:

The most cost-effective method for large print jobs.

The more you print, the cheaper the price per page.

Can accommodate a variety of paper with a degree of custom finishing.

Metallic, fluorescent and other custom inks are available.

Highest possible print quality with precise detail and color fidelity.

In commercial offset printing, the more you print, the less you pay. After the initial cost of setup, it will cost you just a few cents per sheet of paper and ink. If you need to print flyers, brochures, booklets, newsletters and other documents in bulk, an office printer or even a professional digital printer is not the way to go. They are less efficient and more expensive.

If you need to print large quantities quickly, then offset printing can do it. Once the original design has been converted to a plate cylinder, printing to paper only takes a few seconds.

Offset printing produces crisp, well-detailed typography and rich, accurate color images. A typical printer won't be able to match this high level of quality.

This is all the most basic information to answer the question of what offset printing technology is. Hopefully the above article has helped you have a clearer view of the most popular printing technology today.

Find out more related articles:

- What is KCS? How do benefits and KCS work?

- Positive thinking at work, career advantages and tips for maintaining a positive outlook

Contact Buy belts at PACKAGING SOLUTION to get the best price

- PP belt

Pet belts